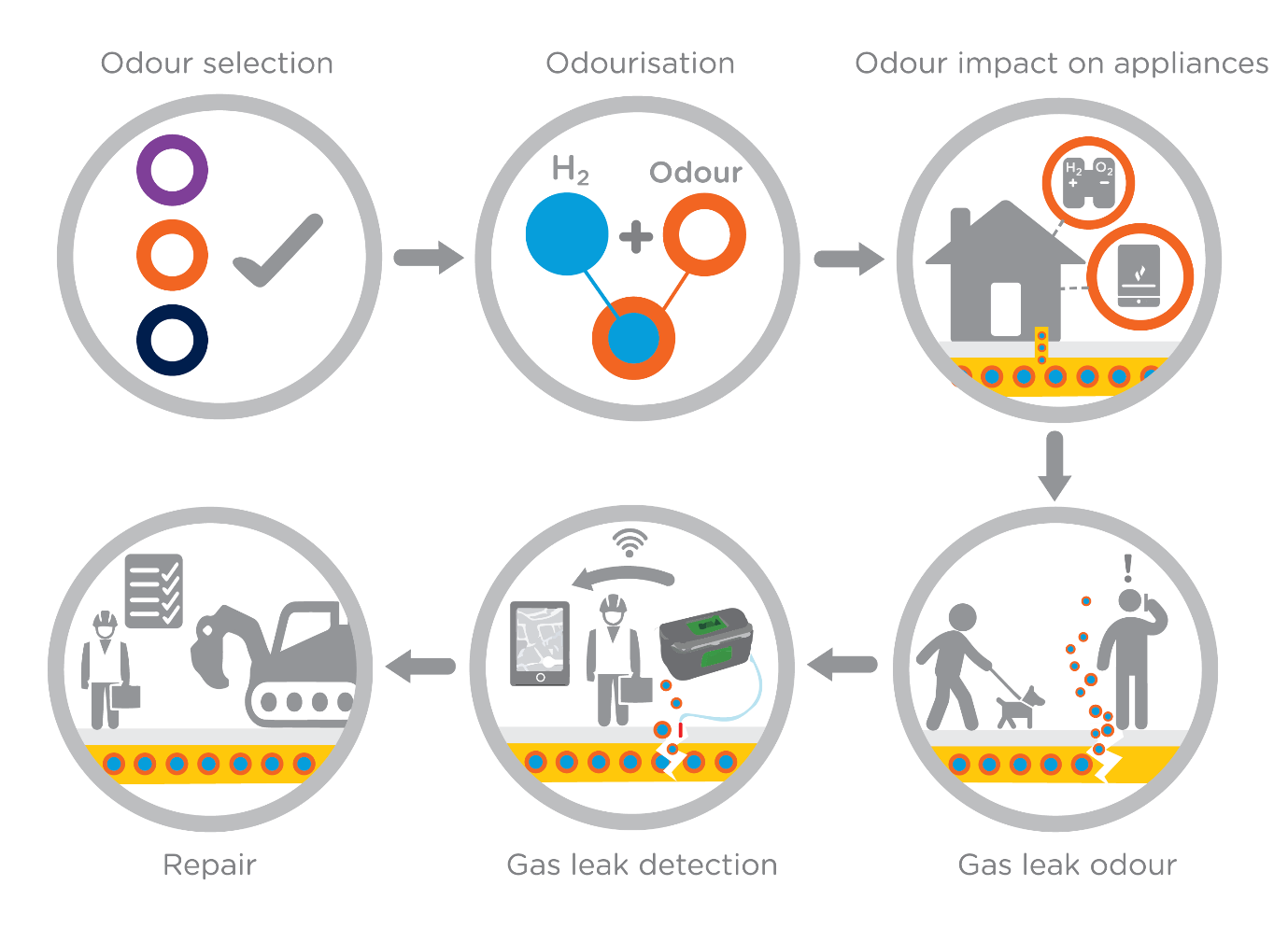

H100 NIA: Hydrogen Odourant & Gas Detection diagram

Project Name: Hydrogen Odourant and Gas Detection

Project Lead: SGN

Partners: NPL

Our Odourant and Gas Detection element of the H100 Fife project is split into two work packages focused on investigating various odourants and portable gas detection instruments for suitability in hydrogen detection.

Odourant

This work package focused on identifying a suitable odourant for use in a 100% hydrogen gas grid and domestic end-use such as boilers and cookers. The research involved a review of existing odorants (used primarily for natural gas), and the selection of five suitable odourants based on the available literature. One odourant was selected based on possible suitability with a fuel cell vehicle which could in future be a possible end-user of grid hydrogen.

Odourisation of natural gas is a simple and effective way of allowing customers to quickly identify a gas escape in the home. Currently in the UK, this odourant is a sulphur-based compound, which can deliver an unpleasant smell even when the natural gas has been diluted to below the lower explosive limit.

For this project we will adopt the same requirement for hydrogen gas by evidencing through laboratory testing and analysis to fully understand whether the currently used odourant is suitable for use in hydrogen, or if an alternative odourant must be used.

Gas Detection

Our Gas Detection phase of this H100 Fife element was developed to assess whether there is a portable gas detection instrument currently available to detect hydrogen in a wide range of concentrations as specified in industry standards (INQ3 and INQ4)

For this assessment, the team identified what detection instruments are available globally that potentially meet the requirements needed for hydrogen detection. Then a review was carried out to assess their suitability for use by our emergency and engineering teams to detect a hydrogen gas leak. These detection instruments required testing in a number of ‘performance requirements’, such as operating under extreme temperatures and pressures, the effects of humidity, the response to different gases (hydrogen and natural gas), the warm up time, time of response and more.

If an instrument was identified as suitable we used it to track and locate any external or internal hydrogen gas escapes. It needed to meet the current specifications for portable gas detection instruments and be compliant with all current industry standards and procedures.

The results established which detectors respond with different sensitivities to natural gas and hydrogen or if a new gas detection instrument is to be created for use on our network.