Our Innovation team is focussing on rolling out new equipment and procedures across all our regions to reduce gas emissions.

Gas escapes are rare but and can be potentially dangerous. They can also cause significant disruptions to gas supplies.

We’ve got two new innovations which are working together to help our engineers improve the way we repair gas escapes. These new tools are already being manufactured and delivered to our equipment stores in Scotland and the south of England, with training for our engineers underway.

Stent bag

Traditionally, we use flow stopping equipment to stop leaking gas mains so our engineers can repair them. Unfortunately, we need to stop gas supplies being fed by the main while we complete the repair.

A Stent Bag is a new flow stopping device which stops the leak while keeping supplies on. Our Innovation team has taken inspiration from the medical industry.

In medicine, a stent is a tiny wire mesh tube, with a balloon catheter, which doctors insert into a blocked artery. The balloon is inflated, reopening the vessel, and the stent expands and locks in place. This holds the artery open to allow blood to flow.

The Stent Bag does something similar in a damaged gas main. It’s inserted into the main at a safe 30m distance from the escape. Then, once it’s pushed into position, it expands to temporarily seal the damage and allow gas to flow through it. This quickly reduces the volume of gas escaping and keeps customer supplies on throughout.

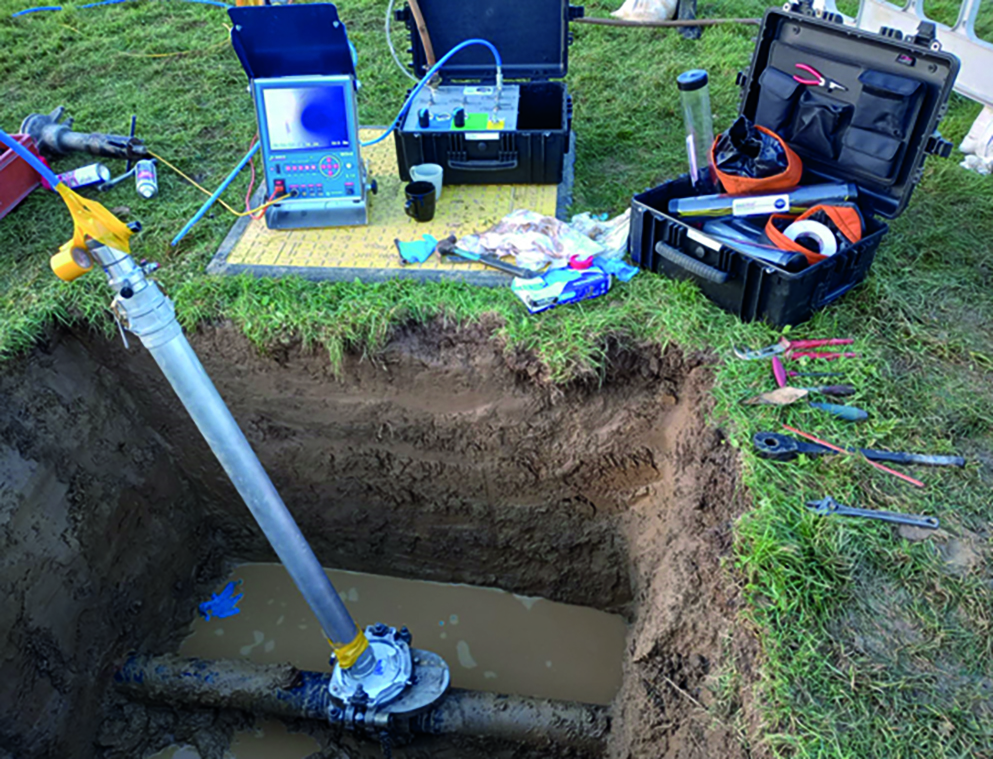

HVGET

The High Volume Gas Escape Toolbox (HVGET) provides a safer and more efficient way of making interim and permanent repairs. The toolbox has four tools, each tailored for specific types of leaks.